Blog

10 Essential Tips for Choosing the Right Heavy Duty Hose for Your Needs

When it comes to tackling demanding tasks, selecting the right heavy duty hose is crucial for ensuring efficiency and durability. Whether you're a professional in construction or landscaping, or simply seeking a reliable solution for home use, understanding the key features and specifications of heavy duty hoses can make all the difference. With a plethora of options available on the market, making a well-informed choice is essential to match your specific requirements.

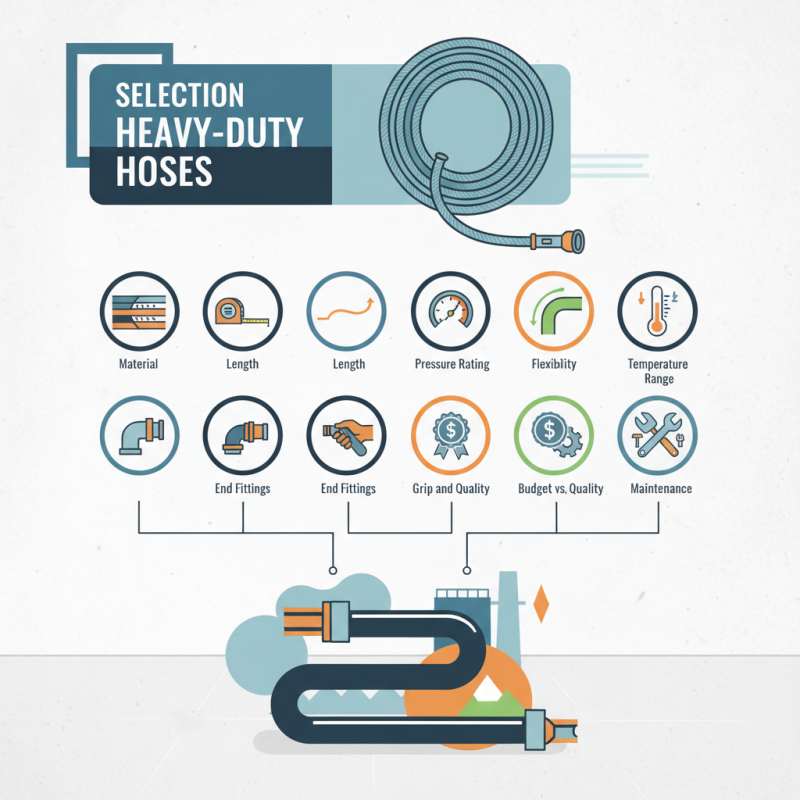

In this guide, we will explore ten essential tips that will help you navigate the decision-making process when selecting a heavy duty hose. From considering the material and length to assessing pressure ratings and flexibility, each factor plays a significant role in performance. By taking the time to evaluate these aspects, you can ensure that your heavy duty hose will withstand the rigors of your tasks and provide dependable service over time. Whether you're dealing with high-pressure applications or need a hose that can handle extreme temperatures, being equipped with the right knowledge will empower you to make the best choice for your needs.

Understanding Different Types of Heavy Duty Hoses Available in the Market

When it comes to selecting the right heavy-duty hose, understanding the various types available is crucial. Heavy-duty hoses are typically categorized by their material composition, intended use, and pressure ratings. For instance, PVC hoses are popular due to their flexibility and resistance to a wide range of chemicals, making them ideal for agricultural applications. In contrast, rubber hoses are known for their durability and strength, providing excellent performance in high-pressure environments and extreme temperatures. According to a recent industry report by MarketsandMarkets, the heavy-duty hose market is projected to reach $10 billion by 2026, highlighting the growing demand for specialized hoses across various sectors.

Another significant factor in choosing a heavy-duty hose is its construction. Hoses reinforced with multiple layers, such as steel wire or polyester, offer enhanced pressure capabilities and structural integrity. The National Hose Association indicates that hoses for industrial use should withstand at least 150 PSI (pounds per square inch), which is critical for applications that demand reliability under stress. Additionally, the choice of diameter and length will depend on the specific requirements of the job at hand, with larger diameters facilitating greater flow rates, while longer lengths may be necessary for extensive coverage. Understanding these distinctions helps users select an appropriate hose that meets their operational needs precisely.

Heavy Duty Hose Comparison: Key Features

Assessing the Specific Conditions and Environments for Hose Usage

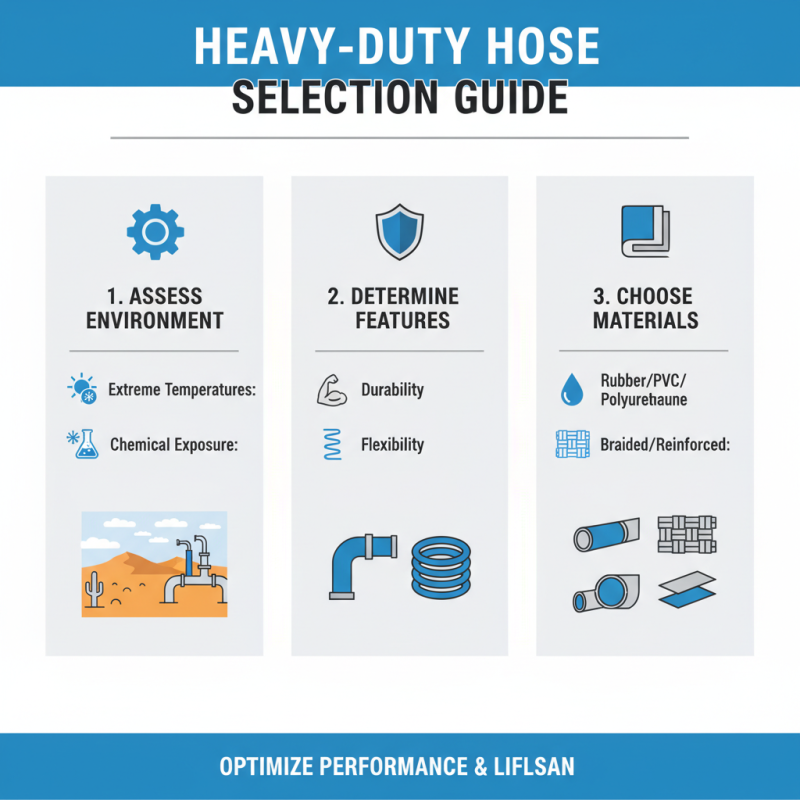

When selecting a heavy-duty hose, it's crucial to assess the specific conditions and environments in which it will be used. Understanding the surrounding environment can help you determine the necessary features of the hose, including its durability and flexibility. For instance, if you plan to use the hose in an area with extreme temperatures or exposure to chemicals, look for materials designed to withstand such conditions.

One essential tip is to consider the hose's required pressure rating. High-pressure applications demand hoses that can handle increased stress without compromising safety or performance. Additionally, evaluate the environment for potential hazards, such as abrasion or excessive bending. A hose with reinforced layers or a protective cover can prevent wear and extend its lifespan.

Another important factor to assess is the mobility required in your workspace. If the hose needs to navigate tight corners or move frequently, lightweight materials and construction will ease handling. Ensuring that the hose can perform optimally in its intended environment will make a significant difference in its efficiency and longevity, ultimately leading to better results in your application.

Evaluating the Material and Durability Features of Heavy Duty Hoses

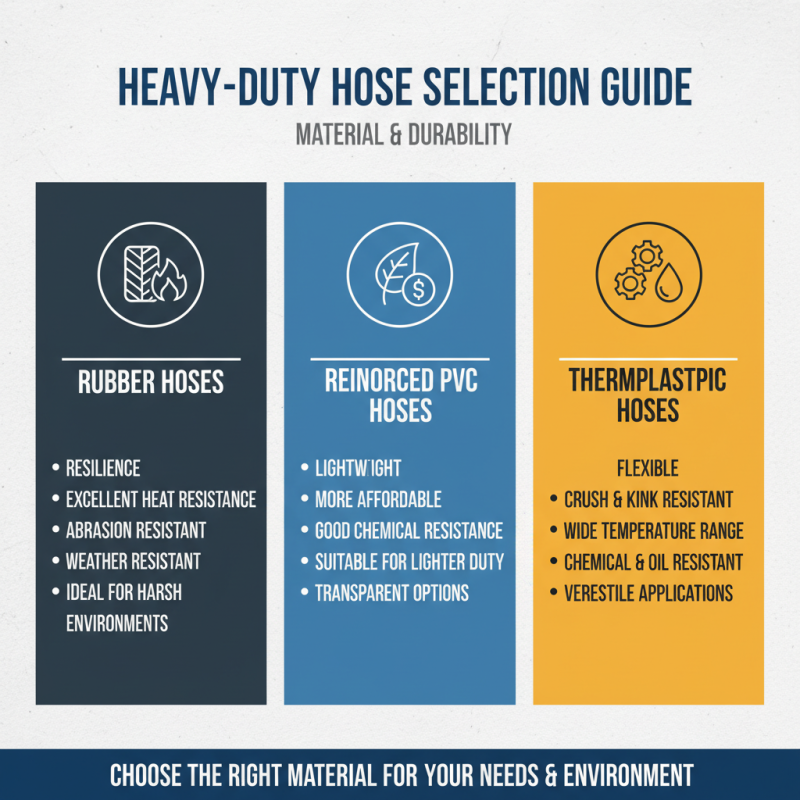

When selecting a heavy-duty hose, evaluating the material and durability features is paramount to ensuring it meets your specific needs. Heavy-duty hoses are typically made from materials such as reinforced PVC, rubber, or thermoplastic, each offering unique advantages. For instance, rubber hoses are known for their resilience, providing excellent resistance to heat, abrasions, and weathering. On the other hand, PVC hoses are lightweight and more affordable, making them suitable for less demanding applications. The choice of material should reflect the environment in which the hose will be used, as well as the substances it will transport.

Durability features, such as burst pressure ratings and kink resistance, are also critical factors to consider. Heavy-duty hoses should be able to withstand high pressure without compromising their integrity. Look for hoses that have been tested for burst strength and have reinforced construction to prevent kinking, which can lead to a loss of flow and potential damage. Additionally, a hose with UV and chemical resistance will ensure longevity when exposed to harsh outdoor conditions or aggressive substances. Ultimately, understanding the material composition and durability features of heavy-duty hoses will guide you towards making a more informed and effective choice for your particular application.

Determining the Correct Hose Diameter and Length for Your Applications

Choosing the right diameter and length for a heavy-duty hose is critical for ensuring optimal performance in various applications. A hose that is too narrow may restrict water flow, leading to inefficiencies and increased pressure on the pump. According to a report by the American Society of Agricultural and Biological Engineers, flow capacity can decrease significantly if the diameter is inadequate, potentially reducing operational efficiency by up to 50% in agricultural applications. On the other hand, a hose that is excessively wide can lead to unnecessary weight and bulk, complicating handling and mobility.

When determining the correct hose length, it is essential to consider both the reach required and the potential for pressure loss over distance. Research published by the Hydraulic Institute indicates that every 100 feet of hose can reduce flow pressure by approximately 5 PSI, depending on factors such as diameter and material. Thus, optimal hose length should be calculated not only by immediate needs but also by accounting for any bends or twists that might occur during use. By carefully evaluating the required diameter and length, users can ensure they select a hose that meets their specific needs without compromising on performance or efficiency.

10 Essential Tips for Choosing the Right Heavy Duty Hose for Your Needs

| Tip Number | Considerations | Recommended Hose Diameter (inches) | Recommended Hose Length (feet) | Common Applications |

|---|---|---|---|---|

| 1 | Understand Pressure Requirements | 1/2 | 50 | Welding, High Pressure Cleaning |

| 2 | Determine Fluid Type | 3/4 | 100 | Water, Chemicals |

| 3 | Assess Temperature Requirements | 1 | 75 | Steam, Hot Water |

| 4 | Analyze Bend Radius Needs | 1 1/2 | 60 | Agricultural Applications |

| 5 | Evaluate Length and Weight | 2 | 150 | Construction, Mining |

| 6 | Check for Abrasion Resistance | 1/4 | 40 | Landscaping, Garden Maintenance |

| 7 | Consider Coupling Type | 3/8 | 30 | Home Use, Plumbing |

| 8 | Look for Kink Resistance | 1/2 | 80 | Commercial Cleaning |

| 9 | Evaluate Durability and Lifespan | 2 1/2 | 200 | Industrial Use, Heavy Equipment |

| 10 | Know Local Regulations | 1 | 100 | Environmental Compliance, Safety Standards |

Identifying Key Safety Standards and Certifications for Heavy Duty Hoses

When selecting heavy-duty hoses, understanding the key safety standards and certifications is crucial for ensuring reliability and performance in demanding environments.

The American Society for Testing and Materials (ASTM) offers comprehensive guidelines that outline the necessary specifications for materials and performance.

According to a report by the Industrial Hose Manufacturers Association (IHMA), nearly 30% of hose failures are attributed to non-compliance with industry safety standards. Ensuring that hoses meet ASTM, ISO, or SAE certifications can significantly reduce the risk of operational hazards in industrial settings.

Additionally, the National Institute for Occupational Safety and Health (NIOSH) emphasizes the importance of proper hose specifications in preventing workplace injuries.

Heavy-duty hoses subjected to high-pressure environments must undergo rigorous testing and certification to confirm they can withstand not just pressure but also exposure to chemicals and temperature variations.

According to research, hoses that comply with NIOSH guidelines can exhibit up to a 50% increase in lifespan compared to those that do not.

Choosing hoses that adhere to recognized safety standards not only protects equipment but also enhances worker safety and compliance with occupational health regulations.

Related Posts

-

The Ultimate Guide to Choosing the Right Marine Hose for Your Boat

-

Top 5 Best Flexible Garden Hoses for Easy Gardening and Hassle Free Watering

-

Transform Your Gardening Experience: The Ultimate Guide to Choosing a Quality Garden Hose

-

Why Are Fire Hoses Essential for Effective Fire Safety and Emergency Response

-

Unleashing the Power of Heavy Duty Hose for Industrial Applications and Beyond

-

What is a Fire Hose? Understanding Types, Uses, and Maintenance Tips