Blog

What is a Fire Hose and How Does It Work?

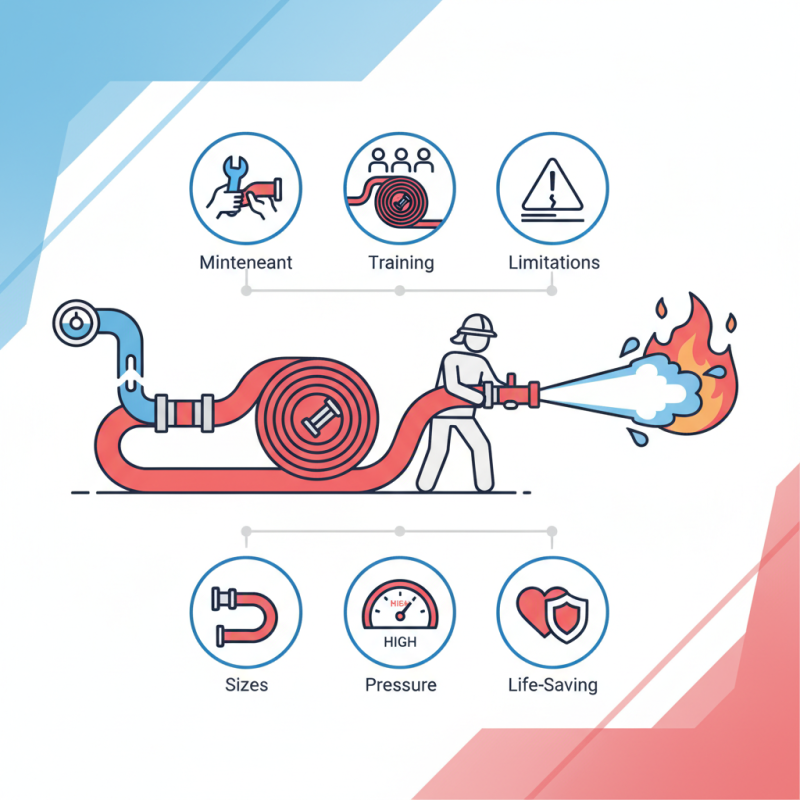

Fire hoses are a vital tool in firefighting. They carry water from a source to extinguish flames. According to John Smith, a fire safety expert, "Fire hoses save lives by delivering immediate water pressure to the fire."

The design and function of fire hoses are crucial for effective firefighting. Made from durable materials, they withstand high pressures. Each hose has different sizes and ratings that determine its use. Choosing the right fire hose can be a matter of life and death.

While fire hoses are essential, they also require regular maintenance and training. Improper handling can lead to dangerous situations. Fire departments must prioritize hose inspections and staff training to ensure efficiency during emergencies. Understanding fire hoses is not just about their function but also about recognizing their limitations.

What is a Fire Hose?

A fire hose is a crucial tool in firefighting. It is designed to transport water from a source, like a hydrant, to combat flames. Fire hoses come in various lengths and diameters, tailored for specific purposes. Their outer layer is often made of durable materials to withstand harsh conditions.

When the firefighter connects the hose to a pump, water flows through it under pressure. The nozzle at the end controls the water's direction and intensity. This allows firefighters to effectively reach high or distant flames. However, using a fire hose requires training. A novice may struggle to handle the pressure, risking injury or accidents.

In emergency situations, coordination is essential. Firefighters must work together, but miscommunication can occur. Hoses can become tangled, causing delays. Each moment counts when lives are at stake. Understanding how fire hoses operate is vital, but there's always room for improvement in training and practice. Fire safety relies on both equipment and the skills of the people who use it.

Fire Hose Usage Statistics

This bar chart represents the average fire hose length and diameter in various fire departments across the United States. The lengths are measured in feet and diameters in inches.

History and Evolution of Fire Hoses

The history of fire hoses dates back to ancient civilizations. The earliest records show the Greeks used leather tubes. These tubes were rudimentary and ineffective for large fires. A simple bucket or cloth often served better in such emergencies.

In the 17th century, fire hoses evolved. Firefighters began using linen or cotton, reinforced with leather for strength. This change allowed easier transport of water. However, early hoses had weak connections, leading to leaks and pressure loss. Many firefighters faced challenges during emergencies due to these flaws.

The 19th century marked significant advancement. Fire hoses became more durable with the introduction of rubber. This material was easier to manufacture and more reliable. Yet, some challenges remained. Firefighters had to deal with heavy hoses that could hinder quick responses. Even today, not every hose design is perfect for all situations. The quest for improvement continues.

Types of Fire Hoses and Their Uses

Fire hoses are critical tools in firefighting operations. Different types of fire hoses serve various purposes. The primary types include attack hoses and supply hoses. Attack hoses, typically ranging from 1.5 to 3 inches in diameter, are designed for delivering water to suppress fires. Notably, they are lightweight and flexible, allowing firefighters to maneuver easily. Supply hoses, on the other hand, are larger, usually around 4 to 6 inches in diameter. They transport large volumes of water from a hydrant to pumpers. According to the National Fire Protection Association (NFPA), the U.S. fire departments respond to over 350,000 fires annually, emphasizing the importance of effective hose systems.

Additionally, there's a growing need for specialized hoses. For instance, foam hoses are used in applications where chemical fire suppression is necessary. These hoses integrate foam through a special nozzle, creating a barrier against flames. Reports show that approximately 30% of firefighting incidents in urban areas involve flammable liquids, heightening the relevance of foam hoses. While traditional hoses are effective, integrating modern materials and technologies is still a challenge. Firefighters often must adapt to various situations, navigating obstacles with equipment that may not always be ideal. The complexity of each fire incident highlights the necessity for continuous improvement in hose design and functionality.

How Fire Hoses Function in Firefighting

Fire hoses are vital tools in firefighting, designed to deliver water under high pressure. When a fire breaks out, every second counts. Fire hoses allow firefighters to combat flames quickly and efficiently. Typically, these hoses can deliver between 100 to 300 gallons of water per minute, depending on the size and type. This rapid delivery is crucial for controlling larger blazes.

The function of a fire hose goes beyond just spraying water. They are equipped with nozzles that can be adjusted for different types of spray patterns. This adaptability allows firefighters to target flames precisely. Reports show that proper nozzle technique can reduce water waste by up to 40%. However, hose management is often overlooked. Firefighters may struggle with hose kinks or improper deployment. This can impede their effectiveness during critical moments.

Training is essential. Fire departments emphasize the importance of hose handling in drills. According to the National Fire Protection Association, nearly 70% of fireground challenges stem from poor equipment management. Regular practice can minimize these issues. Building muscle memory helps firefighters respond instinctively in emergencies, leading to better outcomes. An efficient fire hose system not only saves property but also lives.

Maintenance and Care of Fire Hoses

Fire hoses are essential tools in firefighting, but they require proper care and maintenance. Regular inspection is crucial. Look for any signs of wear, such as cracks or leaks. A small crack can grow into a major problem. Check couplings and fittings for tight seals. These components must function correctly to withstand high pressure.

Cleaning fire hoses is also important. After use, hoses should be flushed with water. This removes any debris or chemicals that may cause damage. Be sure to hang them in a cool, dry place. Moisture can lead to mildew and deterioration. It’s easy to overlook these steps, yet they are vital. Neglecting maintenance can lead to failures during emergencies.

Training personnel on the correct handling of hoses is essential. Even a well-maintained hose can malfunction if used improperly. Encourage continuous education about fire equipment. This ensures everyone understands the importance of care. It’s a team effort that cannot be ignored. Regular checks and training create a safer environment for all.

What is a Fire Hose and How Does It Work? - Maintenance and Care of Fire Hoses

| Dimension | Description | Maintenance Tips |

|---|---|---|

| Material | Typically made of synthetic materials like rubber or PVC, providing durability and flexibility. | Inspect regularly for cuts or wear, replace if damaged. |

| Diameter | Common diameters range from 1.5 inches to 3 inches, affecting flow rate. | Ensure fittings match hose diameter for proper connection. |

| Length | Available in lengths up to 200 feet or more, depending on fire response needs. | Store in loops to prevent kinking and damage. |

| Pressure Rating | Designed to withstand pressures often between 200 to 300 psi. | Test pressure capacity annually to ensure safety and compliance. |

| Storage | Should be stored in cool, dry areas to prolong lifespan. | Avoid exposure to extreme temperatures or sunlight for extended periods. |

Related Posts

-

Why Are Fire Hoses Essential for Effective Fire Safety and Emergency Response

-

What is a Fire Hose? Understanding Types, Uses, and Maintenance Tips

-

Why Choosing the Right Fire Hose Garden Hose Can Improve Your Watering Efficiency by Up to 30%

-

2025 Top 10 Fire Hoses for Every Emergency Response Need

-

Best Fire Hose Manufacturers in 2023 Top Quality Options You Need to Know

-

2025 How to Choose the Best 4 Flexible Hose for Your Needs