Blog

What is a Flexible Hose and How is it Used?

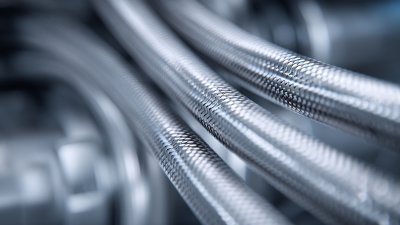

Flexible hoses are essential components in many industries. These versatile tubes can transport liquids and gases efficiently. Their flexibility allows for easy installation in tight spaces. From automotive to manufacturing, flexible hoses serve various purposes.

In automotive applications, flexible hoses connect parts of systems. They handle everything from fuel to coolant. The ability to bend without breaking increases their utility. However, improper use can lead to leaks. Regular inspection is crucial for safety.

In industrial settings, flexible hoses play a critical role. They are used for transferring chemicals and other materials. Often, they must withstand high pressure. Yet, over time, wear and tear can weaken them. Users must understand their limitations to ensure long-lasting performance.

Definition of Flexible Hose and Its Characteristics

A flexible hose is a versatile component used in various industries. It is designed to carry liquids and gases in a safe and efficient manner. Typically made from rubber, plastic, or composite materials, flexible hoses are adaptable to different pressures and temperatures. Their ability to bend easily makes them ideal for applications where space is limited.

The characteristics of flexible hoses include elasticity and resistance to kinking. This means they can be maneuvered easily without damaging the internal structure. Additionally, these hoses can be reinforced with layers to increase durability. Users often appreciate their lightweight nature, which allows for easier handling and installation. However, issues like wear and tear can arise over time, necessitating periodic inspections.

In many cases, the material choice impacts performance. A hose that works well in one environment may fail in another. It’s crucial to consider factors like chemical compatibility and temperature tolerance. Users sometimes overlook these details, leading to leaks or failures. Reflecting on the installation process can reveal potential improvements or adjustments needed for enhanced longevity.

Flexible Hose Usage Characteristics

This chart illustrates the various application areas of flexible hoses and their respective usage percentages across different industries. The data indicates that industrial applications dominate the use of flexible hoses, followed by automotive and medical applications.

Common Materials Used for Flexible Hoses

Flexible hoses are essential components in various industries. They provide versatility in connecting machinery and transporting fluids. The materials used for flexible hoses greatly influence their performance and longevity.

Common materials for flexible hoses include rubber, PVC, and metal. Rubber hoses are popular due to their elasticity and resistance to wear. They can handle high pressures and extreme temperatures. PVC hoses are lightweight and resistant to corrosion. However, they may not withstand high temperatures as well as rubber. Metal hoses, made from stainless steel or other alloys, offer durability and resistance to harsh conditions. They are often used in industries like aerospace.

Regardless of the material, each type has its advantages and drawbacks. For instance, rubber hoses can degrade when exposed to certain chemicals. PVC hoses may become brittle over time. Metal hoses, while strong, can be expensive. Users should consider these factors when choosing a flexible hose. Each application may demand a different approach.

Applications of Flexible Hoses in Various Industries

Flexible hoses are vital in many industries. They transport liquids, gases, and slurries efficiently. Their design allows for easy movement and adaptability. In construction, flexible hoses connect various machinery. They simplify tasks, making it easier to work in tight spaces. Operators appreciate their lightweight nature. However, wear and tear can be an issue. Regular checks are needed to prevent leaks.

In the automotive sector, these hoses are crucial. They are used in fuel systems and cooling systems. High durability ensures vehicles operate smoothly. Mechanics often question whether they can withstand extreme conditions. This requires constant vigilance.

In manufacturing, flexible hoses facilitate the movement of materials. They are essential in processes such as chemical handling. But improper installation can lead to failures. Workers need training to handle these hoses safely.

Ultimately, flexible hoses are indispensable in many fields. They enable efficiency and safety in operations. Yet, as their uses increase, so do the challenges. Addressing these challenges involves continuous learning and adaptation.

Advantages of Using Flexible Hoses over Rigid Piping

Flexible hoses offer numerous advantages over traditional rigid piping systems. One key benefit is the ability to navigate tight spaces and awkward layouts. Flexible hoses can bend and twist, making them perfect for complex installations. This adaptability simplifies the design and reduces potential stress points that can lead to failures in rigid pipes.

Another significant advantage is their lightweight nature. Flexible hoses are much easier to handle and install. This can dramatically cut down labor time and costs. Additionally, their ability to absorb vibrations helps maintain the integrity of connected systems. Rigid pipes, conversely, transfer vibrations that may cause damage over time.

However, despite their many benefits, flexible hoses are not without drawbacks. They may have a shorter lifespan compared to rigid pipes, requiring more frequent replacements. For some applications, this could lead to increased maintenance costs. It's essential to assess the specific needs of your project before opting for flexible hoses or rigid piping. Choosing the right option requires careful consideration of the environment and usage.

What is a Flexible Hose and How is it Used? - Advantages of Using Flexible Hoses over Rigid Piping

| Dimension | Flexible Hose | Rigid Piping | Advantages of Flexible Hoses |

|---|---|---|---|

| Installation | Quick and easy installation | Requires more time and labor | Saves installation costs |

| Flexibility | Highly flexible for dynamic applications | Rigid and fixed positions | Adapts to movement and vibration |

| Maintenance | Easier to inspect and replace | Difficult to access for repairs | Reduced downtime |

| Temperature Resistance | Can handle a variety of temperatures | Limited temperature range | Versatile in different environments |

| Weight | Lightweight and easy to handle | Heavier and cumbersome | Reduces load on structures |

Maintenance and Care Tips for Flexible Hoses

Flexible hoses are essential in various applications, including plumbing and automotive industries. Proper maintenance is crucial for their longevity and reliability. According to a report by the American Society of Mechanical Engineers, regular inspection can increase the lifespan of hoses by up to 30%.

To maintain flexible hoses, check for visible wear and tear. Look for cracks, bulges, or leaks. These are signs that a hose may need replacement. It's often recommended to replace hoses every five years, even if they appear fine. This proactive approach can prevent unexpected failures.

Regular cleaning is also critical. Dirt and debris can accumulate, leading to blockages. A simple rinse with water can help. Avoid using harsh chemicals that might degrade the material. Consider a periodic professional inspection. Neglecting these steps can lead to costly repairs. Many users overlook minor signs of wear. They might think a small leak is negligible. However, ignoring it can escalate into a significant problem over time.

Related Posts

-

Understanding the Benefits of 4 Flexible Hose for Home and Industrial Applications

-

2025 How to Choose the Best Flexible Hoses: Top Trends & Expert Insights

-

The Science Behind Flexible Hoses and Their Impact on Modern Plumbing Technology

-

Understanding the Essential Role of Industrial Hose Manufacturers in Modern Industries

-

2025 How to Choose the Best 4 Flexible Hose for Your Needs

-

The Ultimate Guide to Choosing the Right Flexible Gas Hose for Your Needs