Blog

The Science Behind Flexible Hoses and Their Impact on Modern Plumbing Technology

The advent of flexible hoses has revolutionized modern plumbing technology, offering unparalleled versatility and convenience in various applications. According to a report by MarketsandMarkets, the global flexible hoses market is projected to reach $3.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.1% from 2020 to 2025. This surge is largely attributed to the increasing demand for lightweight, durable, and adaptable plumbing solutions in both residential and commercial settings.

Flexible hoses provide significant advantages over traditional rigid pipes, including ease of installation, resistance to corrosion, and the ability to accommodate movement and vibration. As plumbing systems become increasingly sophisticated, understanding the science behind flexible hoses is crucial for optimizing performance and efficiency. This guide will delve into the types, benefits, and applications of flexible hoses, showcasing their pivotal role in shaping the future of plumbing technology.

Understanding the Basics: What Are Flexible Hoses in Plumbing?

Flexible hoses have become an essential component in modern plumbing, offering versatility and ease of installation that traditional piping often lacks. These hoses are particularly useful in applications where rigid pipes are impractical, such as in tight spaces or for connecting appliances. According to the Plumbing and Mechanical Services Association, flexible hoses can reduce the number of joints needed, which helps to minimize potential leak points, ultimately enhancing the reliability of the plumbing system.

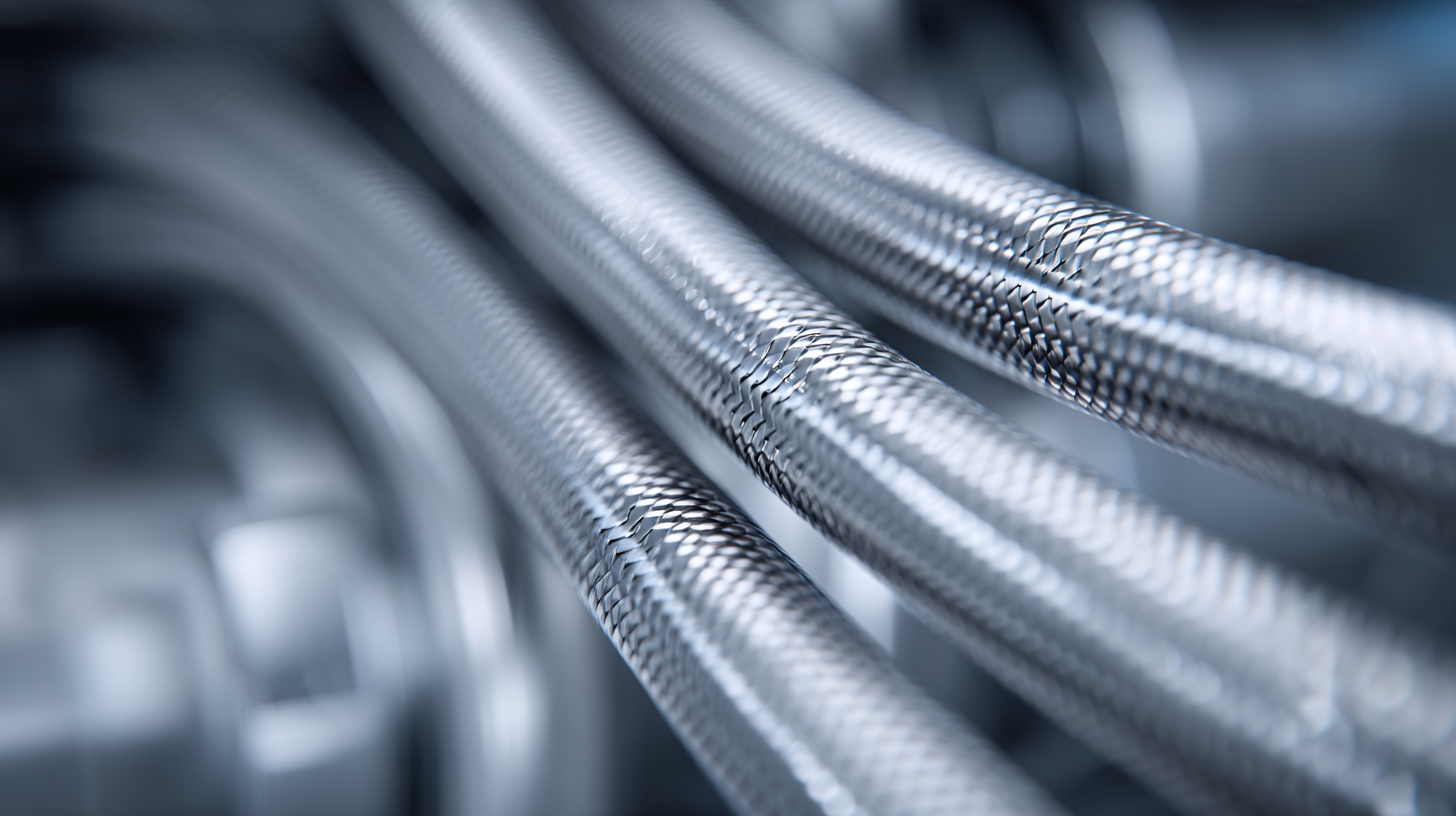

Understanding the basics of flexible hoses involves recognizing the materials they are made from, which commonly include rubber, PVC, and stainless steel. Each material offers distinct advantages, such as flexibility, corrosion resistance, and pressure handling capabilities. For instance, stainless steel braided hoses can withstand high pressures and are typically used in high-demand environments. Moreover, flexible hoses have been shown to improve water flow and reduce pressure loss, making them a key player in energy-efficient plumbing systems. As highlighted by industry experts, regular maintenance of these hoses is vital to ensure their longevity and effectiveness, which is a focus of events like the upcoming Plumbing Made Simple presentation in Vancouver.

The Advantages of Flexible Hoses Over Traditional Rigid Piping

Flexible hoses have revolutionized plumbing technology, offering numerous advantages over traditional rigid piping systems. According to a report by the Plumbing Manufacturers International (PMI), flexible hoses can reduce installation time by up to 30%, allowing for quicker project completion. This is particularly beneficial in commercial environments where downtime can significantly impact productivity. The lightweight nature of flexible hoses also leads to lower transportation costs and easier handling during installation, further enhancing efficiency.

Flexible hoses have revolutionized plumbing technology, offering numerous advantages over traditional rigid piping systems. According to a report by the Plumbing Manufacturers International (PMI), flexible hoses can reduce installation time by up to 30%, allowing for quicker project completion. This is particularly beneficial in commercial environments where downtime can significantly impact productivity. The lightweight nature of flexible hoses also leads to lower transportation costs and easier handling during installation, further enhancing efficiency.

Moreover, flexible hoses exhibit superior adaptability, allowing for adjustments in tight spaces and around obstacles without the need for additional fittings or connectors. A study published in the Journal of Construction Engineering and Management indicates that the use of flexible hoses can minimize the risk of leaks and failures, as they absorb vibrations and thermal expansions better than rigid pipes. This adaptability is crucial in residential plumbing, where the layout can often be irregular. Additionally, flexible hoses are resistant to corrosion and can withstand various pressures, thus contributing to the longevity and reliability of plumbing systems. Overall, the advantages of flexible hoses mark a significant advancement in modern plumbing, showcasing their effectiveness and practicality in various applications.

Key Materials Used in Modern Flexible Hose Manufacturing

Flexible hoses have become an integral part of modern plumbing technology, and their manufacturing relies on a variety of advanced materials. The key materials utilized in the production of flexible hoses include thermoplastics, rubber compounds, and metal reinforcements. Thermoplastics, such as PVC and polyurethane, are favored for their durability, flexibility, and resistance to chemicals, making them ideal for various plumbing applications. Rubber compounds, often blended with additives, enhance the hoses’ resilience against temperature fluctuations and environmental conditions. Metal reinforcements, such as stainless steel braiding, provide additional strength and prevent kinking, ensuring longevity and reliability in demanding environments.

Moreover, the focus on renewable energy and sustainable practices is driving the market for flexible hoses. As industries seek to reduce their environmental impact, manufacturers are exploring eco-friendly alternatives in material sourcing and production processes. By incorporating recycled materials or bio-based plastics, the flexible hose industry is not only advancing technological capabilities but also aligning itself with the broader movement towards sustainability. This shift not only supports market growth but also encourages innovative approaches in product design and application, ultimately enhancing the effectiveness of plumbing systems across various sectors.

Impact of Flexible Hoses on Water Efficiency and Leakage Prevention

Flexible hoses have profoundly transformed modern plumbing technology, particularly in enhancing water efficiency and preventing leaks. According to industry reports, flexible hoses can reduce water wastage by up to 30% when compared to traditional rigid pipes. Their design allows for greater adaptability and maneuverability, making it easier to navigate tight spaces and awkward angles. This flexibility is not only convenient but also contributes to a more efficient plumbing system, ensuring that water flows smoothly without unnecessary obstructions.

Flexible hoses have profoundly transformed modern plumbing technology, particularly in enhancing water efficiency and preventing leaks. According to industry reports, flexible hoses can reduce water wastage by up to 30% when compared to traditional rigid pipes. Their design allows for greater adaptability and maneuverability, making it easier to navigate tight spaces and awkward angles. This flexibility is not only convenient but also contributes to a more efficient plumbing system, ensuring that water flows smoothly without unnecessary obstructions.

Leakage prevention is another significant advantage of flexible hoses. Studies indicate that around 10% of residential water use can be attributed to leaks in traditional plumbing systems. Flexible hoses, often equipped with advanced leak-proof fittings, significantly minimize the risk of such leaks. The latest data shows that using modern flexible hoses can cut down on leakage incidents by nearly 50%, highlighting their effectiveness in maintaining water integrity. Overall, the innovative materials and design of flexible hoses play a crucial role in promoting sustainability and efficiency in plumbing systems.

Practical Tips for Maintaining and Sizing Flexible Hoses in Your Home

Maintaining flexible hoses is crucial for ensuring the efficiency and longevity of modern plumbing systems. Regular inspections are essential; homeowners should check hoses for signs of wear, such as cracks, bulges, or leaks. Replacing damaged hoses promptly not only prevents water loss but also mitigates the risk of water damage to your home. It’s also advisable to clean the connectors and ensure that they are free from debris to avoid any blockages that could hinder water flow.

When sizing flexible hoses, it’s important to consider the specific requirements of your plumbing system. Measure the distance between connections and choose hoses that are slightly longer than needed to accommodate any bends or turns in the layout. This allows for flexibility in installation without putting undue stress on the fittings. Additionally, selecting hoses made from durable materials, such as reinforced rubber or stainless steel, can enhance performance and prevent leaks, providing peace of mind for homeowners. Proper sizing and maintenance of flexible hoses can significantly improve the overall plumbing efficiency in any home.

Related Posts

-

Understanding the Benefits of 4 Flexible Hose for Home and Industrial Applications

-

Understanding the Essential Role of Industrial Hose Manufacturers in Modern Industries

-

Understanding the Advantages of Fire Hose Garden Hose Combinations for Efficient Watering Techniques

-

The Ultimate Guide to Choosing the Right Flexible Gas Hose for Your Needs

-

Understanding the Latest Innovations in Marine Hose Technology: Boosting Efficiency and Safety in Marine Operations

-

Understanding the Essential Role of Gas Tubing in Modern Energy Solutions