Blog

Why Flexible Tubing is Essential for Modern Applications and How to Choose It

In today's rapidly evolving industrial landscape, the demand for versatile and efficient solutions is more critical than ever. One such solution is flexible tubing, an essential component in various applications across multiple sectors, including healthcare, automotive, food and beverage, and beyond. The adaptability of flexible tubing allows it to accommodate a wide range of materials and environmental conditions, making it a preferred choice among engineers and designers. Its lightweight nature, combined with the ability to bend and twist without compromising performance, opens up numerous possibilities, ensuring that systems can be optimized for both functionality and space constraints.

Choosing the right flexible tubing, however, requires careful consideration of several factors, including material composition, temperature resistance, pressure ratings, and compatibility with a wide array of fluids and gases. Each application poses unique challenges, demanding that professionals understand not only the characteristics of different tubing materials but also the specific requirements of their systems. By delving into the crucial elements that make flexible tubing indispensable in modern applications, this guide will shed light on how to make informed decisions when selecting the ideal tubing solution for specific needs.

Importance of Flexible Tubing in Modern Industrial Applications

Flexible tubing plays a pivotal role in modern industrial applications, providing efficient solutions across various sectors. Its adaptability allows for seamless integration in systems involving fluid and gas transfer. Industries such as pharmaceuticals, food and beverage, and automotive greatly benefit from the inherent flexibility of tubing, enabling them to navigate complex layouts and reduce the risk of leaks or ruptures. Moreover, the lightweight nature of flexible tubing offers ease of installation and maintenance, making it an essential component in today's fast-paced environment.

When choosing flexible tubing, consider factors such as material compatibility, temperature range, and pressure ratings. For instance, certain applications may require tubing that can withstand extreme temperatures or resist chemical corrosion. It's crucial to perform a thorough assessment to select the right type that aligns with specific operational needs.

Tips: Always consult with an expert when selecting materials to ensure optimal performance. Additionally, evaluate the tubing's flexibility against the operational requirements; too rigid may lead to potential breakage, while overly flexible might not provide the necessary support. Regular maintenance checks can also help in identifying wear and ensuring longevity in various applications.

Common Materials Used in Flexible Tubing and Their Properties

Flexible tubing plays a crucial role in a myriad of modern applications, serving industries that range from automotive to pharmaceuticals. The choice of material for flexible tubing is vital, as it directly affects performance, durability, and compatibility with various fluids. Common materials include PVC, silicone, rubber, and polyolefin, each possessing distinct properties that cater to specific needs.

PVC tubing is known for its versatility and cost-effectiveness, making it ideal for general-purpose applications.

Silicone tubing, on the other hand, is highly resistant to temperature extremes and is often used in medical and food-related applications.

Rubber tubing is valued for its elasticity and strength, making it suitable for high-pressure environments.

Lastly, polyolefin tubing is lightweight and resistant to chemicals, which makes it a preferred choice for industrial uses.

Tips for selecting the right flexible tubing: always consider the application requirements, such as temperature range and chemical exposure. Additionally, ensure the tubing meets the necessary regulatory standards for your industry. Testing samples of the tubing in real-world conditions can help assess their performance before making a bulk purchase.

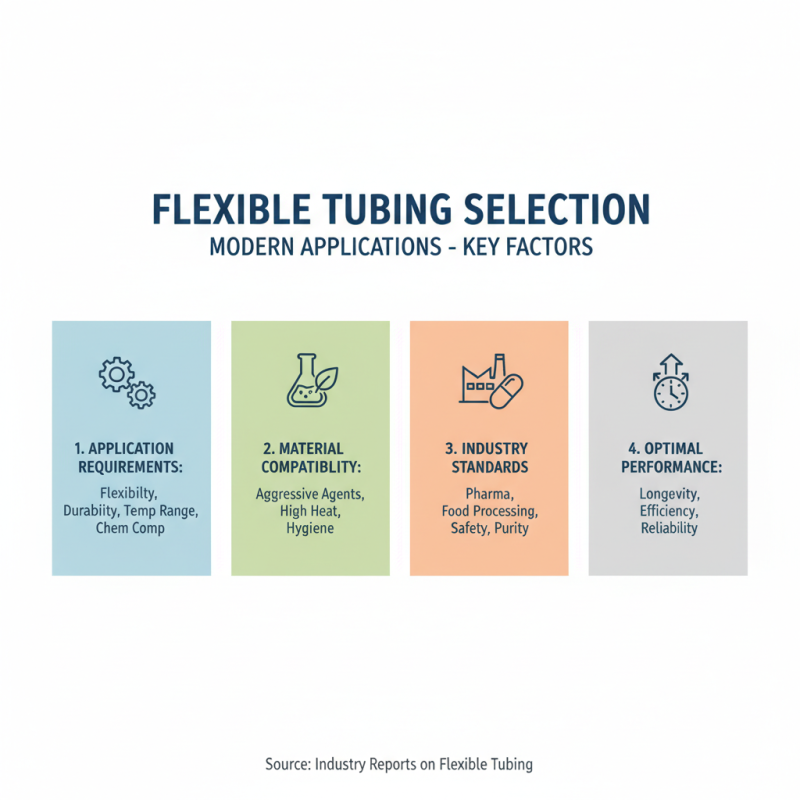

Key Factors to Consider When Choosing Flexible Tubing

When selecting flexible tubing for modern applications, several key factors must be carefully evaluated to ensure optimal performance and longevity. First and foremost, understanding the specific requirements of the application is crucial. The flexibility, durability, chemical compatibility, and temperature range of the tubing all play vital roles in its suitability. Reports indicate that industries such as pharmaceuticals and food processing demand tubing that adheres to stringent safety and hygiene standards, often requiring materials that can withstand high temperatures and aggressive cleaning agents.

Another critical factor to consider is the tubing's diameter and wall thickness. According to a recent industry analysis, improper sizing can lead to inefficiencies such as pressure drops and compromised flow rates, affecting system performance. For example, in fluid transfer applications, choosing tubing with an inadequate diameter can restrict flow, resulting in reduced operational efficiency. Furthermore, the choice between reinforced and unreinforced types is essential depending on the application’s pressure requirements; reinforced tubing is often necessary for high-pressure environments, particularly in manufacturing settings where safety is paramount.

Lastly, evaluating the tubing's compliance with relevant industry standards is essential. Tubing must meet certification requirements such as FDA or ISO standards, especially in regulated industries. An industry study highlighted that companies adhering to these standards manage to reduce failure rates by up to 30%, significantly improving their operational reliability. Therefore, making informed decisions based on these factors is critical for ensuring the selection of the right flexible tubing that not only meets operational needs but also enhances overall system efficiency.

Applications of Flexible Tubing Across Various Industries

Flexible tubing plays a crucial role across various industries due to its adaptability and versatility. In the medical sector, for instance, the global flexible tubing market size was valued at approximately $7.8 billion in 2022, as reported by industry analysts. Its application ranges from surgical instruments to drug delivery systems, where the ability to bend and maneuver through tight spaces is essential. The increasing demand for minimally invasive procedures has further fueled the growth of flexible tubing, as products like catheters and biopharmaceutical equipment require materials that can navigate complex anatomical structures while ensuring patient safety.

Similarly, in the automotive industry, flexible tubing is indispensable for efficient fluid transfer. According to a report by a leading market research firm, the automotive flexible tubing market is projected to grow at a CAGR of 6.5% between 2023 and 2030. Here, the tubing is utilized in fuel lines, air conditioning systems, and brake fluid applications, where resilience to temperature variations and chemical exposure is critical. The emphasis on lightweight materials in vehicle manufacturing has also led to increased innovation in flexible tubing, paving the way for enhanced durability and performance without adding significant weight.

In the industrial sector, flexible tubing is integral for transferring gases and liquids in manufacturing processes. Research indicates that the industrial flexible tubing market will witness steady growth, driven by advances in manufacturing technology and automation. Characteristics such as flexibility, pressure resistance, and compatibility with various chemicals are vital, as industries ranging from chemicals to food processing rely on streamlined operations facilitated by robust tubing solutions. The potential for customization and the ability to withstand harsh environments further underscore the importance of flexible tubing in modern industrial applications.

Maintenance and Care Tips for Flexible Tubing Longevity

To ensure the longevity of flexible tubing, regular maintenance and care are crucial. It is essential to perform routine inspections to check for signs of wear, cracks, or any degradation. Cleaning the tubing with appropriate solvents, when necessary, can prevent buildup of residues that may affect performance. Avoid exposing flexible tubing to extreme temperatures or harsh chemicals that could compromise its integrity. A well-maintained tubing system will not only enhance efficiency but also minimize the risk of unexpected failures.

In addition to routine checks, proper storage and installation practices play a significant role in prolonging the lifespan of flexible tubing. When storing tubing, it should be kept in a cool, dry environment away from direct sunlight to prevent degradation from UV exposure. During installation, ensure that bends are smooth rather than sharp, and avoid over-tightening connections to reduce stress on the material. By adhering to these maintenance and care guidelines, users can optimize the performance of flexible tubing in various applications, ensuring that it remains reliable and functional over time.

Flexible Tubing Usage in Various Industries

This bar chart illustrates the percentage of flexible tubing usage across various industries. Automotive applications lead with 30%, followed by food and beverage at 25%, pharmaceutical at 20%, construction at 15%, and chemical processing at 10%. The data highlights the importance of flexible tubing in modern applications.

Related Posts

-

The Ultimate Guide to Choosing the Right Flexible Gas Hose for Your Needs

-

10 Best Flexible Gas Hoses for Safe and Efficient Gas Supply

-

Understanding the Latest Innovations in Marine Hose Technology: Boosting Efficiency and Safety in Marine Operations

-

2025 How to Choose the Best Flexible Hoses: Top Trends & Expert Insights

-

What is a Fire Hose? Understanding Types, Uses, and Maintenance Tips

-

Transform Your Gardening Experience: The Ultimate Guide to Choosing a Quality Garden Hose