Blog

2025 How to Choose the Best 4 Flexible Hose for Your Needs

When it comes to selecting the right 4 flexible hose for your specific applications, the choices can often be overwhelming. With a multitude of options available in the market, understanding the key factors that influence hose performance and suitability is crucial for making an informed decision. Flexible hoses are essential components in numerous industries, including plumbing, automotive, and manufacturing, where they provide vital functionality by facilitating the transfer of liquids and gases.

In this guide, we will explore the core aspects to consider when choosing the best 4 flexible hose for your needs. From material composition to pressure ratings and temperature tolerances, each criterion plays a significant role in ensuring that the hose not only meets but exceeds your operational requirements. By delving into the specific applications and environments in which the hose will be utilized, you can streamline your options and select a product that enhances efficiency and reliability in your operations. Whether you are a seasoned professional or a DIY enthusiast, understanding these essential factors will empower you to make the best choice for your flexible hose needs.

Understanding Flexible Hoses: Types and Applications in 2025

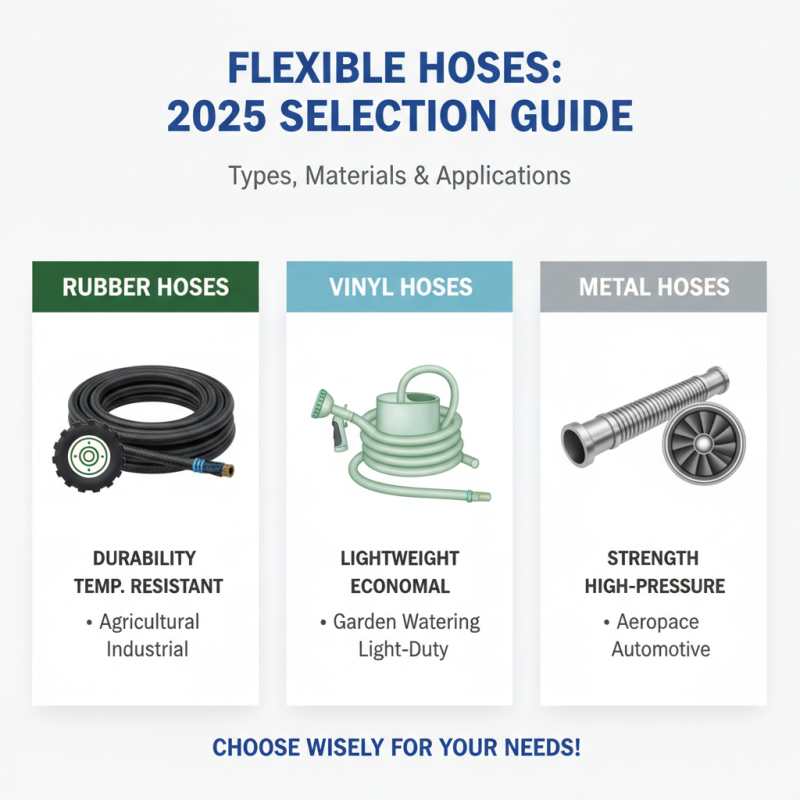

In 2025, understanding the different types of flexible hoses and their specific applications is crucial for making informed decisions when selecting the best option for your needs. Flexible hoses come in various materials and designs, each tailored for unique functionalities. Common types include rubber hoses, vinyl hoses, and metal hoses. Rubber hoses are often chosen for their durability and resistance to extreme temperatures, making them ideal for agricultural and industrial applications. Vinyl hoses are lighter and more economical, commonly used for garden watering and light-duty tasks, whereas metal hoses, known for their strength and flexibility, are perfect for high-pressure or high-temperature environments, commonly found in aerospace and automotive industries.

When considering the application of flexible hoses in 2025, it’s essential to evaluate factors like operating environment, flexibility requirements, and compatibility with fluids or gases. For example, chemical resistance is a critical factor when selecting hoses for laboratory or industrial chemical transport. Another consideration is the length and diameter of the hose, which will affect flow rates and pressure drops. Therefore, customization options may be necessary, and understanding the limitations and strengths of each type of hose can significantly impact efficiency and safety in their intended applications.

Key Factors to Consider When Selecting Flexible Hoses for Your Projects

When selecting the best flexible hoses for your projects, there are several key factors to consider. First, it is essential to assess the material composition of the hose. Different materials, such as rubber, PVC, and silicone, offer various advantages in terms of flexibility, durability, and resistance to environmental factors such as temperature and chemicals. Understanding the specific requirements of your application will help you choose a hose that not only meets operational needs but also ensures longevity and safety.

Another critical factor is the hose diameter and length. The size of the hose directly affects the flow rate and pressure capacity, influencing its suitability for different projects. A hose that is too narrow may restrict fluid flow, while one that is excessively long can lead to significant pressure drops. Additionally, consider the operating conditions, such as whether the hose will be exposed to high pressures or temperatures, which can impact material performance. By taking into account these factors, you will be better equipped to select a flexible hose tailored to your precise requirements, enhancing the overall efficiency and success of your project.

2025 How to Choose the Best 4 Flexible Hose for Your Needs - Key Factors to Consider When Selecting Flexible Hoses for Your Projects

| Flex Hose Type | Material | Max Pressure (psi) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Rubber Hose | Synthetic Rubber | 300 | -40 to 185 | Water, Air |

| Stainless Steel Hose | Stainless Steel | 1500 | -320 to 1500 | Oil, Gas, Chemicals |

| PTFE Hose | PTFE (Teflon) | 2000 | -100 to 500 | Corrosive Fluids |

| Vinyl Hose | PVC | 150 | 32 to 140 | Water, Low Pressure Applications |

Material Properties: Evaluating Rubber, PVC, and Metal Flexibility

When selecting the ideal flexible hose for various applications, understanding the material properties is crucial. Rubber hoses, known for their outstanding flexibility and durability, can withstand temperatures ranging from -20 to 180 degrees Fahrenheit. According to a report by the Flexible Hose Manufacturers Association (FHMA), rubber hoses have a bending radius approximately 20% less than their PVC counterparts, making them suitable for tight spaces and dynamic movements. Rubber’s inherent resilience allows it to endure high pressures, often rated to over 300 psi, ensuring reliability in demanding environments.

On the other hand, PVC hoses offer a lightweight and cost-effective alternative with good flexibility. They maintain performance in temperatures from 32 to 140 degrees Fahrenheit. Recent industry analyses indicate that PVC hoses can handle pressures typically up to 150 psi. However, their flexibility can be compromised under extreme conditions, limiting their use in high-stress applications. In contrast, metal hoses, while more rigid, possess excellent temperature resistance and pressure capabilities that far exceed both rubber and PVC options, making them ideal for high-temperature and high-pressure systems. The choice between these materials ultimately hinges on specific application requirements, emphasizing the need for a thorough evaluation of flexibility, durability, and environmental factors before making a decision.

Industry Trends: How 2025 Innovations Impact Hose Selection Criteria

In 2025, the evolution of flexible hose technology is set to redefine how industries approach hose selection criteria. As innovations emerge, the emphasis on durability, temperature resistance, and flexibility becomes more pronounced. Manufacturers are increasingly developing hoses that incorporate advanced materials, providing greater resilience to extreme conditions, which is vital for industries such as construction and manufacturing where performance and safety are paramount.

When choosing the best flexible hose for your needs, consider these tips: First, assess the working environment and the specific fluids or gases the hose will transport. This understanding will guide you in selecting hoses designed to withstand the unique challenges of your application. Second, keep an eye on the latest developments in hose technology. Innovations such as lightweight yet strong composites can significantly improve handling and efficiency. Lastly, prioritize hoses that offer resistance to wear and aging, ensuring that your investment holds up over time and reduces maintenance costs.

The impact of these trends is not just on efficiency and safety; they also entail potential cost savings. Selecting hoses that are well-suited to their applications can minimize downtime and reduce the likelihood of equipment failure. As we move forward, staying informed about these advancements will be key to making effective hose selections in a rapidly evolving industrial landscape.

2025 Innovations Impact on Hose Selection Criteria

Performance Standards: Ensuring Compliance with ISO and ASTM Guidelines

When selecting flexible hoses, adherence to performance standards such as ISO and ASTM guidelines is crucial to ensure reliability and safety in various applications. The International Organization for Standardization (ISO) sets out specifications that can enhance hose performance, ensuring they withstand the demands of high-pressure environments. According to the latest data from ISO reports, over 70% of industries that implement ISO-compliant products report fewer operational failures and increased efficiency. Compliance with these standards not only improves safety but also optimizes the performance of the hoses in industrial settings.

ASTM International, another key player in establishing quality benchmarks, provides guidelines that cover material properties, design specifications, and testing methods for flexible hoses. Recent studies indicate that equipment failures linked to non-compliant hoses can lead to significant financial losses, potentially as high as 15% of operational costs annually. By investing in hoses that meet ASTM standards, companies can mitigate risks associated with leaks or ruptures, which are often caused by inferior materials that fail under pressure.

Ensuring that flexible hoses comply with both ISO and ASTM standards is critical in maintaining operational integrity and enhancing overall safety protocols within various industries.

Related Posts

-

Understanding the Benefits of 4 Flexible Hose for Home and Industrial Applications

-

Understanding the Essential Role of Industrial Hose Manufacturers in Modern Industries

-

The Science Behind Flexible Hoses and Their Impact on Modern Plumbing Technology

-

Top 5 High Quality Garden Hoses to Elevate Your Gardening Experience in 2023

-

2025 How to Choose the Best Flexible Hoses: Top Trends & Expert Insights

-

2025 Top 10 Fire Hoses for Every Emergency Response Need