Blog

What Are Industrial Hoses? Types, Uses, and Key Considerations Explained

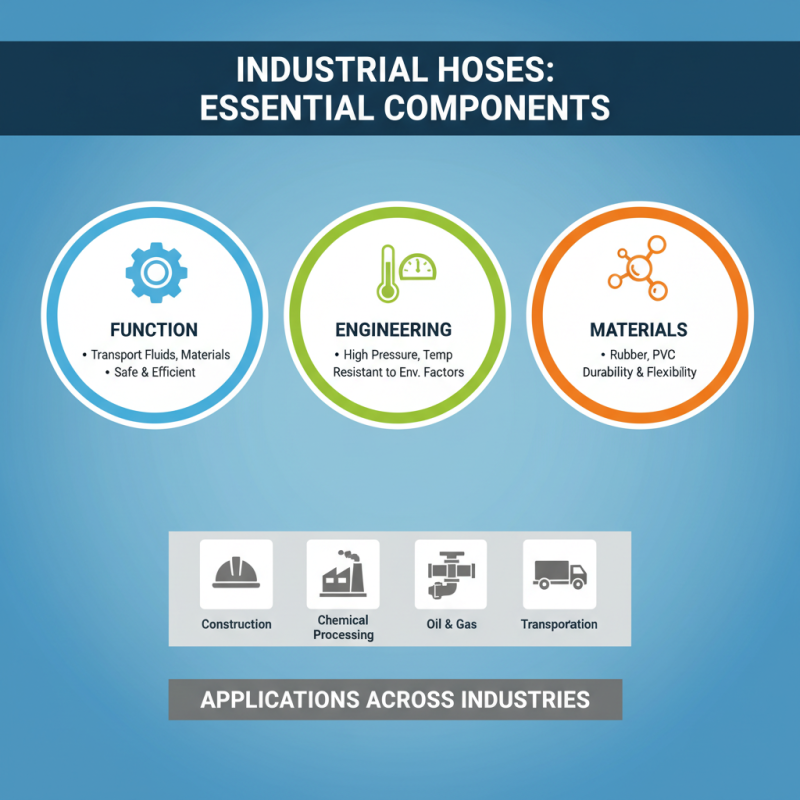

In the world of manufacturing and industrial operations, the importance of industrial hoses cannot be overstated. These versatile tubes are essential for the transfer of various materials, including liquids, gases, and even bulk solids, across diverse sectors such as construction, agriculture, and chemical processing. According to Dr. Michael Anderson, an expert in industrial fluid systems, "The efficiency and safety of an operation often hinge on the quality and suitability of the industrial hoses used." This highlights the critical role these components play in ensuring smooth and safe operations in industrial settings.

Industrial hoses come in a range of types, each tailored to specific applications and materials. From reinforced rubber hoses designed for high-pressure applications to lightweight PVC options for less demanding tasks, understanding the different types is crucial for selecting the right hose for any industrial need. Factors such as temperature, pressure, and chemical compatibility must be carefully considered to prevent leaks, bursts, or other failures. As industries evolve, the demand for innovative hose solutions is likely to grow, making it essential for professionals to stay informed about new developments and technologies in the field.

Understanding Industrial Hoses: A Comprehensive Overview

Industrial hoses are essential components across various industries, designed to transport fluids, gases, and other materials safely and efficiently. These hoses are engineered to withstand high pressures, temperatures, and various environmental factors, making them crucial for tasks ranging from construction to chemical processing. Understanding the intricacies of industrial hoses involves recognizing their material compositions, which can range from rubber and PVC to metal and composite materials, each tailored to specific applications. The choice of material directly impacts the hose's durability, flexibility, and resistance to chemicals or abrasives.

In addition to material considerations, the design and configuration of industrial hoses play a significant role in their functionality. Factors such as diameter, length, and fitting types must align with the operational requirements to ensure seamless integration into existing systems. Professionals must also be mindful of the hose's operating conditions, including temperature ranges and pressure levels, to avoid potential failures. Regular maintenance and inspections are essential to prolong the lifespan of industrial hoses, ensuring they meet safety standards and operational demands. Overall, understanding industrial hoses involves a comprehensive look at their types, uses, and key performance considerations, enabling industries to optimize their processes effectively.

Types of Industrial Hoses: Categorization by Material and Application

Industrial hoses are crucial components in a variety of applications, designed to transport fluids, gases, and other materials safely and efficiently. The categorization of industrial hoses can primarily be divided based on the materials used in their manufacturing, including rubber, PVC, silicone, and metal, as well as their specific applications within different industries.

Rubber hoses, known for their flexibility and durability, are widely used in sectors ranging from construction to agriculture. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications like transferring hydraulic fluids. According to a report by Research and Markets, the global market for rubber hoses is projected to reach $6.85 billion by 2023, demonstrating their essential role in industrial processes.

On the other hand, PVC hoses are favored for their lightweight and chemical resistance, often utilized in plumbing and irrigation systems. Silicone hoses are highly effective for high-temperature applications, particularly in the automotive sector, where they can maintain performance even under extreme conditions. A recent study shows an increasing demand for silicone hoses, with growth anticipated at a CAGR of 5.6% from 2023 to 2030, reflecting a significant trend in the industrial hose market for versatile materials that meet specific performance requirements across diverse industries.

What Are Industrial Hoses? Types, Uses, and Key Considerations Explained

| Type of Industrial Hose | Material | Applications | Pressure Rating (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Rubber Hose | Synthetic Rubber | Water, Air, Oil Transfer | 150-300 | -20 to 180 |

| PVC Hose | Polyvinyl Chloride | Chemicals and Water | 60-150 | 32 to 130 |

| Stainless Steel Hose | Stainless Steel | High-Pressure Applications | 1500-3000 | -320 to 1500 |

| Composite Hose | Multiple Layers | Fuel and Petroleum Products | 150-300 | -40 to 190 |

| Silicone Hose | Silicone Rubber | Food and Beverage | 50-150 | -40 to 500 |

Common Uses of Industrial Hoses Across Various Industries

Industrial hoses are essential components in a wide range of industries due to their ability to transport various fluids and materials safely and efficiently. In manufacturing, hoses are often utilized for conveying water, chemicals, and other substances in processes such as cooling, cleaning, and chemical injection. Their durability and flexibility allow manufacturers to maintain workflows while minimizing the risk of leaks and spills, which can disrupt operations and pose environmental hazards.

In the construction industry, industrial hoses play a crucial role in transferring concrete, slurry, and other building materials to various locations at construction sites. These hoses are designed to withstand high pressures and abrasive materials, ensuring that the heavy-duty demands of construction activities are met. Additionally, they are also vital in the agricultural sector for irrigation systems and transporting pesticides and fertilizers. Overall, the versatility of industrial hoses makes them indispensable across various applications, providing solutions that enhance operational efficiency and safety in different working environments.

Common Uses of Industrial Hoses Across Various Industries

Key Considerations When Selecting Industrial Hoses for Your Needs

When selecting industrial hoses for specific applications, several key considerations come into play that can significantly impact performance and durability. One of the foremost factors is the compatibility of the hose material with the substances it will transport. For instance, data from the Industrial Hose Market Analysis report indicates that the chemical resistance of the hose material must align with the type of fluid or gas to prevent degradation and ensure safety during operations. Failure to account for this can lead to costly downtime and potential hazards.

Another critical aspect is the hose's pressure and temperature rating, which are essential for ensuring operational efficiency. According to the Institute for Supply Management, hoses must be evaluated for their ability to withstand the maximum operating pressure and temperature of the application. Selecting hoses with inadequate ratings can result in premature failure, leading to leaks or bursts that pose risks to both personnel and equipment. Additionally, the hose's flexibility and bend radius should also be considered, particularly in applications requiring tight routing or frequent movement, as insufficient flexibility can lead to mechanical wear and eventual breakdown.

In conclusion, selecting the right industrial hoses goes beyond just material and size; it requires a thorough understanding of the specific needs of the application, supported by industry data and standards to ensure safety and reliability in operations.

Maintenance and Safety Practices for Industrial Hose Usage

When it comes to the effective use of industrial hoses, maintenance and safety practices play a crucial role in ensuring both efficiency and longevity. Regular inspection is essential; hoses should be checked for signs of wear, leaks, and abrasions. A systematic approach to maintenance includes cleaning hoses using appropriate solutions to avoid build-up of debris or chemicals that can compromise integrity. Moreover, ensuring that all connections are secure can prevent accidents and enhance performance.

Tips: Always handle industrial hoses with care to avoid kinks and bends that can lead to structural damage. Additionally, it is advisable to store hoses properly when not in use—preferably coiled in a manner that prevents twists or crush points. Educating employees on proper handling can further mitigate risks.

Safety practices are just as critical as maintenance. Implementing a clear protocol for hose usage, including the proper pressure limits and temperature ratings, can prevent dangerous blowouts. Providing adequate training for staff on the specifications and handling practices specific to each type of hose is vital for maintaining a safe working environment. Regularly revisiting safety guidelines and integrating them into routine training ensures that everyone remains aware of best practices.

Related Posts

-

Understanding the Essential Role of Industrial Hose Manufacturers in Modern Industries

-

10 Essential Tips for Choosing the Right Industrial Hoses for Your Business

-

Why Choose a Flexible Garden Hose for Your Gardening Needs

-

2025 Top 10 Fire Hoses for Every Emergency Response Need

-

Exploring the Evolution of Garden Hoses: Innovations Driving Water Efficiency in 2023

-

10 Best Flexible Gas Hoses for Safe and Efficient Gas Supply